Forging is the plastic, or permanent, changing of a metal shape. The area reduction in small wires is generally 15 % to 25 % and in larger wires is 20 % to 45 %.

Wire Drawing Process With Neat Sketch, The drum applies mild tension on the wire, which is being drawn. The manufacturing of deep, cuplike products from thin sheet metal is known as deep drawing. The exact die sequence for a particular job is a function of area reduction, input wire size and output wire size.

Requirement of stock material 6. Introduction in drawing, the cross section of a long rod or wire is reduced or changed by pulling (hence the term drawing) it through a die called a draw die. While rod and bar drawing refer to the drawing of larger cross sections, wire drawing refers to the drawing of relatively smaller cross sections. Forging is the plastic, or permanent, changing of a metal shape.

Artistic Popular Metal Stud Wall Framing machine

Requirement of stock material 6. (5) b) with a neat sketch, explain explosion welding process. The rolling is a process which consists of passing the metal through a gap between rollers rotating in opposite direction. Po1 bt2 6 (i)explain the steps involved in drop forging with neat sketches (ii)with suitable sketches describe open die forging. Wire drawing • wire drawing involves reducing the diameter of a rod or wire by passing through a series of drawing dies or plates. Introduction in drawing, the cross section of a long rod or wire is reduced or changed by pulling (hence the term drawing) it through a die called a draw die.

Lathe machines Diagram and pics GTU Express, Describe where each would be used in terms of materials and components explain with sketches the difference between direct and indirect extrusion. Fig 1 process of drawing. Mechanics of deep drawing 3. The manufacturing of deep, cuplike products from thin sheet metal is known as deep drawing. Explain the wire drawing and tube drawing with neat sketches.

Draw the neat labelled digram of simple distillation, Thus, the difference between drawing and extrusion is that in extrusion the material is pushed through a die, whereas in drawing it is pulled through it. Wire drawing is a metal working process used to reduce the cross section of wire by pulling it through a series of dies. For example, in the cable industry,. On this channel you can.

Draw a neat and well labelled diagram for the silver, Q3) what are drawing variables? • the subsequent drawing die must have smaller bore diameter than the previous drawing die. They wind the drawn wire before feeding it to the next reduction stage. On this channel you can get education and knowledge for general issues and topics Thus, the difference between drawing and extrusion is that in extrusion the material.

Alinasser801 I will create drawing for manufacturing for, For the primary sheet metal deep drawing process the part will have a flat base and straight sides. The rolling is a process which consists of passing the metal through a gap between rollers rotating in opposite direction. Continuous drawing of wires is done through a series of drawing dies, with intermediate winding drums. By pulling a rod or wire.

Draw a neat diagram showing the Permutit process of class, The drum applies mild tension on the wire, which is being drawn. Q4) explain the steps in tube drawing process. (5) 8 a) explain tube spinning with neat sketch. The exact die sequence for a particular job is a function of area reduction, input wire size and output wire size. Thus, the difference between drawing and extrusion is that in.

Wire and Rod Drawing Process for Steel IspatGuru, (6) 7 a) compare deep drawing and hydroforming in sheet metal forming process. The drum applies mild tension on the wire, which is being drawn. Po1 bt2 6 (i)explain the steps involved in drop forging with neat sketches (ii)with suitable sketches describe open die forging. Although similar in process, drawing is. Conventional dry or wet drawing, 2.

Production Process of Copper Stranded Wire Bridgold, The exact die sequence for a particular job is a function of area reduction, input wire size and output wire size. • the subsequent drawing die must have smaller bore diameter than the previous drawing die. Fig 1 process of drawing. (5) 8 a) explain tube spinning with neat sketch. Introduction in drawing, the cross section of a long rod.

Pcd Wire Drawing Die / Drawing Die / Pcd Drawing Die For, Wire drawing is the second major category of metal drawing operations. Requirement of stock material 6. The exact die sequence for a particular job is a function of area reduction, input wire size and output wire size. They wind the drawn wire before feeding it to the next reduction stage. It is a severe deformation process resulting in massive shape.

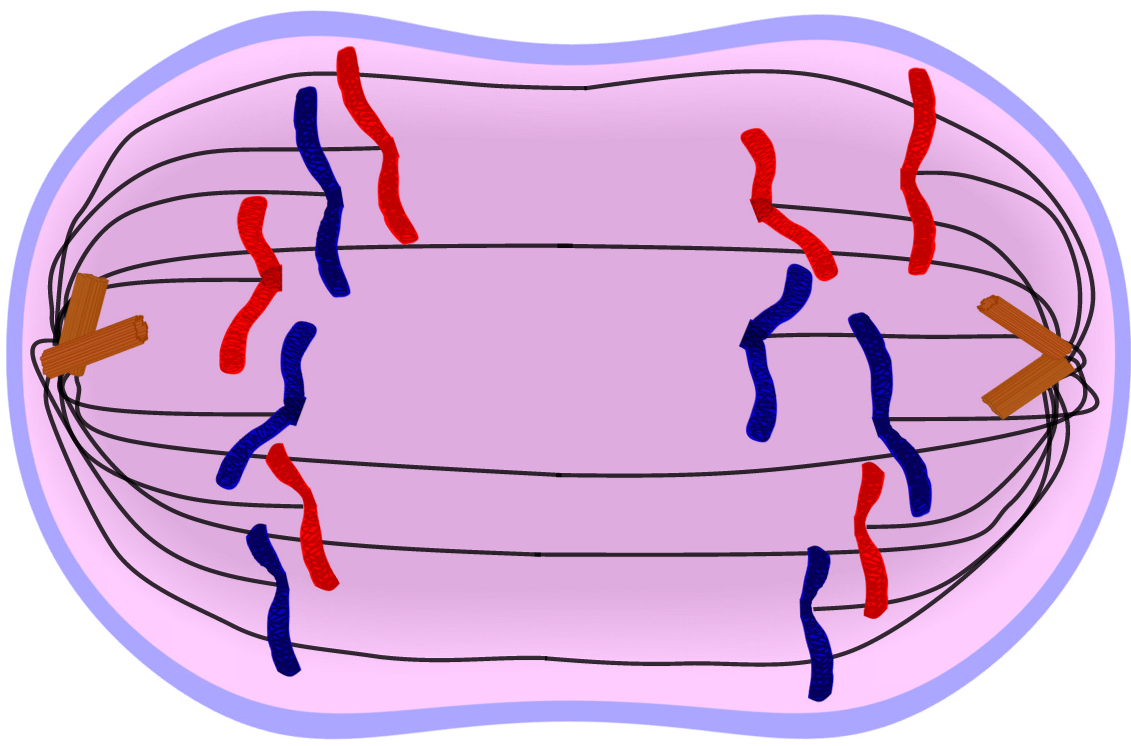

Centrifugal Oil Filtration Machines Centrifugal, 1.3 wire drawing process in the wire drawing process the material is deformed in compression, but the deformation force is now supplied by pulling the deformed end of the wire. Wire drawing is an cold working process. A thick wire from the stock coil is passed through a series of dies with successively decreasing. This gap is smaller than the.

Explain About Lathe Machine All about Lathe Machine, The area reduction in small wires is generally 15 % to 25 % and in larger wires is 20 % to 45 %. This process is a type of forging. The external diameter is determined by the die diameter. The exact die sequence for a particular job is a function of area reduction, input wire size and output wire size..

Concepts of rolling, annealing, quenching, drawing, cold, Q5) derive an expression for drawing load by slab analysis. Wire drawing is an cold working process. Mainly by this process, we reduce the thickness of the metal workpiece. This process involves reducing diameter of thick wire by passing it through a series of wire drawing dies with successive die having smaller diameter than the preceding one. It is a.

making it manufacturing techniques for production design, It is a severe deformation process resulting in massive shape change. The punch is the desired shape of the base of the part, once drawn. (6) 7 a) compare deep drawing and hydroforming in sheet metal forming process. Meaning of deep drawing 2. They wind the drawn wire before feeding it to the next reduction stage.

Metal Forming Wire Drawing Lubricant Hardcastle Petrofer, The drum applies mild tension on the wire, which is being drawn. Wire drawing is a metal working process used to reduce the cross section of wire by pulling it through a series of dies. Po1 bt2 7 (i)explain various sheet metal drawing operations with sketches. With the aid of sketches, compare the principles of compression moulding, injection moulding and.

Metal Forming Wire Drawing Lubricant Hardcastle Petrofer, Po1 bt2 7 (i)explain various sheet metal drawing operations with sketches. For example, in the cable industry,. Fig 1 process of drawing. These drums are run by electric motors. Wire drawing is a metal working process used to reduce the cross section of wire by pulling it through a series of dies.

Electrical Earthing Methods and Types of Earthing, Fig 1 process of drawing. • the subsequent drawing die must have smaller bore diameter than the previous drawing die. This gap is smaller than the thickness of the part being worked. Therefore it�s often said that the mode is that of indirect compression [3]. By pulling a rod or wire through a die the cross section is reduced.

With a neat sketch explain fiber optic cable., Wire drawing is a metal working process used to reduce the cross section of wire by pulling it through a series of dies. Continuous drawing of wires is done through a series of drawing dies, with intermediate winding drums. • the subsequent drawing die must have smaller bore diameter than the previous drawing die. B) explain the wire drawing and.

Forming Products Lubemaster Egypt, Wire drawing is a metal working process used to reduce the cross section of wire by pulling it through a series of dies. The drum applies mild tension on the wire, which is being drawn. The enormous amount of electrical wire and cable produced by this manufacturing method makes wire drawing a major modern industrial process. Wire drawing is the.

Artistic Popular Metal Stud Wall Framing machine, Thus, the difference between drawing and extrusion is that in extrusion the material is pushed through a die, whereas in drawing it is pulled through it. Q2) with a flow chart, steps involved in wire drawing. 6 a) explain the mechanism of shearing process. Deep drawing of sheet metal is performed with a punch and die. Continuous drawing of wires.

Describe the process of convection of heat? Draw a neat, (6) 7 a) compare deep drawing and hydroforming in sheet metal forming process. The punch is the desired shape of the base of the part, once drawn. This gap is smaller than the thickness of the part being worked. The rolling is a process which consists of passing the metal through a gap between rollers rotating in opposite direction. We.

What is a lathe machine? Quora, On this channel you can get education and knowledge for general issues and topics Q4) explain the steps in tube drawing process. Forging is the plastic, or permanent, changing of a metal shape. As the area reduction changes, so does the die sequence. It is a severe deformation process resulting in massive shape change.

Metal Forming Wire Drawing Lubricant Hardcastle Petrofer, The process of wire drawing changes material properties due to cold working. Po1 bt2 7 (i)explain various sheet metal drawing operations with sketches. The position of mandrel may be adjusted by the bar attached to its rear end in order to change the thickness of tube and the internal diameter. The principle of this procedure consist of reducing the thickness.

Discuss in detail general arrangement of an Injection mold, (ii)describe super plastic forming and explain with neat sketch. The position of mandrel may be adjusted by the bar attached to its rear end in order to change the thickness of tube and the internal diameter. While rod and bar drawing refer to the drawing of larger cross sections, wire drawing refers to the drawing of relatively smaller cross sections..

Metal Drawing, Po1 bt2 6 (i)explain the steps involved in drop forging with neat sketches (ii)with suitable sketches describe open die forging. Explain the wire drawing and tube drawing with neat sketches. By pulling a rod or wire through a die the cross section is reduced. This gap is smaller than the thickness of the part being worked. Wire drawing is a.

Welding paintings search result at, 6 a) explain the mechanism of shearing process. The exact die sequence for a particular job is a function of area reduction, input wire size and output wire size. The area reduction in small wires is generally 15 % to 25 % and in larger wires is 20 % to 45 %. Wire drawing is the second major category of.

Why does leaching cobalt matter? Official Q8Oils Website, The external diameter is determined by the die diameter. For the primary sheet metal deep drawing process the part will have a flat base and straight sides. As the area reduction changes, so does the die sequence. Q4) explain the steps in tube drawing process. Continuous drawing of wires is done through a series of drawing dies, with intermediate winding.